Repair-Chat

This page is for any comments, pictures, stories or information you might want to impart to the site that don't necessarily

fit anywhere else on the website.

There are rules!

Primarily don't be rude, offensive or obnoxious, for more details CLICK HERE

See Older Posts

Upt'North ¹ said :-

Ian, you've got me all twitchy. In a good way.

Those Cobalt drills sound like something I need in the tool kit. Well I want them, I may never need them.

I've had a quick looksie on the interweb thingymabob and the prices are all over the shop. Is there a make and type you could recommend?

I've seen screwfix do Bosch 5% Cobalt at a reasonable price but I'd probably prefer to buy a set from somewhere if possible.

Ta me duck.

Upt.

25/04/2024 18:53:31 UTC

Ren - The Ed¹ said :-

Yes I'm unfamiliar with cobalt drills and now I'm intrigued. It'd be nice to have a set of drill bits that actually drills by cutting rather than wearing away the metal.

26/04/2024 07:38:13 UTC

Ian Soady¹ said :-

The ones I got are from toolstation - a small set up to 6mm diameter. I was really impressed. The link shows them. I confess I was also unaware of cobalt - just shows how technology rolls on. I don't expect they'll cope with hardened steel but they made short work of the screws - plus a bit of surrounding flange..... A tenner is a reasonable price, and I'll keep them for drilling stainless and other awkward materials. The trouble with stainless is it work hardens so if using anything but a really sharp drill it will start to skid and ultimately overheat to the point the drill bit itself softens.

Oh and it's a Land Rover not a Kand Rover. Typing skills are deserting me.

https://www.toolstation.com/cobalt-drill-bit-set/p40442...

26/04/2024 10:27:47 UTC

Upt'North ¹ said :-

Ta me duck.

Upt.

26/04/2024 12:59:20 UTC

nab301 said :-

Interesting , likewise I was unaware of cobalt although the suppliers reviews are mixed to say the least!

Nigel

26/04/2024 15:51:42 UTC

Ian Soady¹ said :-

Most of the toolstation reviews are very positive. And as I say, at a tenner you can't go very far wrong.

27/04/2024 10:32:24 UTC

Upt'North ¹ said :-

Ordered my HSS Co drills, I'll post about them when they arrive. No toolstations near here Ian, unfortunately. Nearest is a hour away. Pffffffftttttt. Whose idea was it to live here! Oh yes, mine. Pffffffftttttt.

Started working on The B yesterday now the permafrost has left the garage. First thing to tackle is the buzzy engine bars, it's a well reported Givi fault, the remedy for now will involve two MIRA shower washers, a 3/4 inch tap washer, heat shrink, a longer bolt and a penny washer. What could go wrong. You can just about see the MIRA rubbers on the connector, GIVI supply thin O'rings which rip and fall off within a very short period of time. Not their finest moment. Blummin Italians.....pffffffftttttt.

They should stick to pasta.

Upt.

30/04/2024 11:20:15 UTC

30/04/2024 11:20:15 UTC

Upt'North ¹ said :-

I forgot.....and......insulation tape. You can't do anything without tape! Pffffffftttttt.

30/04/2024 11:22:39 UTC

Upt'North ¹ said :-

Finished! What's next?

I decided to add a nyloc lock nut as just in case. In case of what.....who knows?

30/04/2024 17:18:31 UTC

30/04/2024 17:18:31 UTC

Upt'North ¹ said :-

Ian,

These arrived today. Similar price to yours. Thanks again for the heads up.

Upt.

01/05/2024 16:32:02 UTC

01/05/2024 16:32:02 UTC

Ian Soady¹ said :-

Look good, and the 8mm will be useful. Let us know how they work (I'm sure you will!)

02/05/2024 10:08:05 UTC

Ian Soady¹ said :-

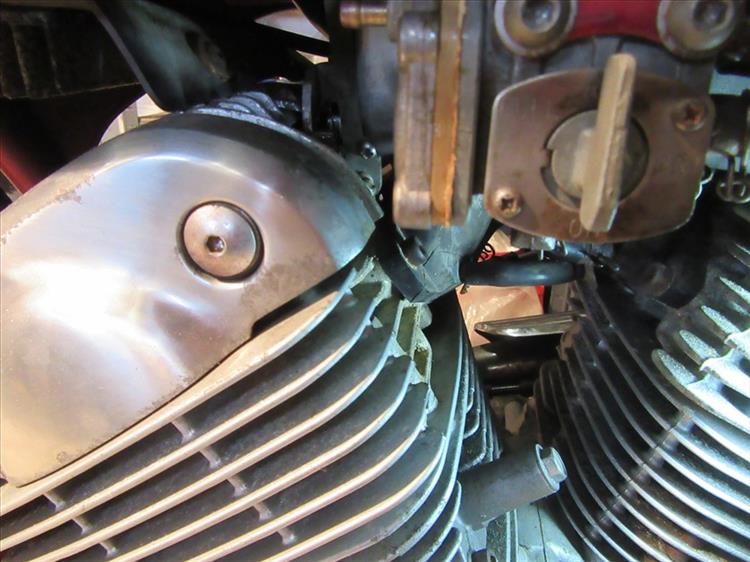

OK. Reattached the exhaust using nuts & bolts - a pig to get the nut on behind (see pic of top one) - I realised for the bottom one it was easier to put the bolt through from the back & put the nut on the front. Fortunately for once Suzuki provided broad enough flanges.

They weren't quite so helpful with the throttle stop screw. I hunted for this for ages before finally discovering it...

CMSNL had the parts but were very slow - ordered on the 20th and not sent till the 26th, but did arrive on the 30th. Far from cheap as well.

Anyway, up and running now and sounds pretty good.

The exhaust flange:

02/05/2024 11:00:35 UTC

02/05/2024 11:00:35 UTC

Ian Soady¹ said :-

And hunt the throttle stop screw:

02/05/2024 11:01:02 UTC

02/05/2024 11:01:02 UTC

Ren - The Ed¹ said :-

So from the head I'm guessing there's a 90 degree bend then a flange, which you have drilled out the M6 threads and inserted M6 nuts and bolts. I hoped you used stainless nuts and bolts. How does the 90 degree bend mate to the head? Is it part of the casting (unlikely) or bolted on as per usual with blind threads and usually crusty bolts?

V-Twins have quite a few mechanical benefits regarding primary and secondary balance improvements, packaging considerations and engine characteristics. They're also a blummin pain in the rear regarding carb access and oft times cooling balance.

Is it ready to ride?

02/05/2024 12:22:01 UTC

Ian Soady¹ said :-

"So from the head I'm guessing there's a 90 degree bend then a flange, which you have drilled out the M6 threads and inserted M6 nuts and bolts."

Correct. And a last resort would have been to try to remove the bend which I think would have been just as hard and ended up with me removing the head..... I just used bolts I had from the bolt tin although the nuts are stainless.

Delving further I removed the carbs and have discovered the float needles were sticking so they need a clean. I suppose I'd better take the jets out and clean them as well. The carbs are a bit odd - to me at least - as the main body is sideways on rather than vertical. Weirder and weirder.

03/05/2024 09:49:41 UTC

Ren - The Ed¹ said :-

Ahh, the bolt tin. I have a bolt drawer. Explain about the carbs? I suppose this will be to do with being a V-Twin.

03/05/2024 13:02:42 UTC

Ian Soady¹ said :-

And the beat goes on.....

I have 2 biscuit tins of assorted metic nuts bolts etc - one for up to 8mm, the other for the bigger stuff. What always amazes me is that I have plenty of bolts with no corresponding nuts, or in other instances nuts with no bolts. I do of course have small bins of Cycle thread sorted by size, and similar for UNF.

Yes, the carbs are odd in that the inlets point straight up, the outlets straight down and sit in rubber sleeves with inaccessible clamps which then mate with angled inlet ports. The slide thus moves horizontally from left to right of the bike. Speaking of which, one diaphragm was in perfect condition, the other had a few small areas where the base material was visible through the rubber but no splits. Replacements are available but about £50 apiece so I've used superglue to repair the defects. I've been successful with this method in the past.

To be honest I'm wondering how it ran at all and am starting to understand why it was cheap - £1150 was, in truth, a good price so I can forgive it some foibles. Close examination of the receipt the vendor sent me does state it is a project - a word that strangely was omitted from the original ad. My brother, who went to have a look at the bike for me, did say he wouldn't buy it. But what does he know, riding as he does a modern Bonneville and an early 1950s AJS 500?

03/05/2024 13:45:53 UTC

Ian Soady¹ said :-

Well I think finally I may have cracked it.

The CMS parts arrived eventaully so refilled with fresh oil, fitted the filter and completed the mod to the exhaust flange.

I put everything back together and put some petrol in the tank, opened the main tap and after half an hour had petrol dripping from the back of the main (left hand) tap. It was coming from the non-return valve mentioned by people elsewhere. So I stripped that out, cut a 1/4" Cycle thread in the exit stub, fitted a setscrew coated with welleal and filled the other side with JB weld. Left to cure overnight then reassembled and it looks petrol-tight, at least so far.

MoT booked for Thursday morning!

07/05/2024 12:23:42 UTC

Ren - The Ed¹ said :-

Good luck with the MOT, but I'm sure you know enough to fix anything that the inspector might pick up on before you get there.

I'm not sure how I'd feel living with a tank that's been repaired. I come from a time where anything remotely glue or filler type was crap. Anything I glued would become unglued, anything I filled would eventually become unfilled. The problem is probably 2-fold. Firstly bad preparation and implementation on my behalf, being a feckless bodger. Secondly the quality of glues and fillers has (apparently) greatly improved over the years, or so I'm told.

Car windows are bonded into place just fine these days, they don't fall out on their own. Many ally and composite chassis are also bonded without issue.

08/05/2024 10:37:07 UTC

Ian Soady¹ said :-

It's not the tank that's been repaired it's the daft non-return valve which I've disabled. I've successfully used JB weld in a number of cases and it usually works well - but I probably wouldn't try to fix a tank with it. Although I did use a specialised epoxy to stick the filler cap adaptor I made to the sadly vanished XBR.

This little Yamaha (a soulful V twin according to the side panels) had the most complex fuel system I've ever come across but now much simplified.

Briefly, petrol arrives at the tap, which is one the left hand side under the tank, via two pipes from the tank - one main on (with presumably a stand pipe in the tank) and one reserve. The tap has 3 positions: main, reserve and prime. Let's ignore prime for the moment.There is a tap under the tank which can close these off but it's inaccessible without lifting the tank which of course requires the seat to be removed.

When main or reserve are selected and the engine is running providing vacuum via the front cylinder, fuel then passes to the RHS where there's another vacuum controlled device (to the left in the pic). This is both a further tap and a pump, again driven by vacuum from the rear cylinder. Fuel is then delivered to a fuel rail above the carbs. At the other end of this rail is a pipe which is the one previously mentioned ie in the pic.

Where this pipe connects to the tap is a pressure actuated non-return valve which when actuated allows fuel from the rail back into the tank via the two pipes(!). It's the bit with the pipe attached in the pic. My assumption is that this is there so that if the pump creates too much pressure in the fuel rail it will bleed off excess.

This whole thing is massively complicated and to my mind totally unnecessary. My only possible explanation is that as the carbs are quite high up (although below the bottom of the tank) the designers thought there may not be enough head to fill the carbs. But if that was the case the prime position wouldn't work (it delivers fuel to the RHS regardless of vacuum).

08/05/2024 13:13:46 UTC

08/05/2024 13:13:46 UTC

Name

Comment

Add a RELEVANT link (not required)

Upload an image (not required) -

Uploading...